info@zhengchengmech.com +86-372-2598052

info@zhengchengmech.com +86-372-2598052

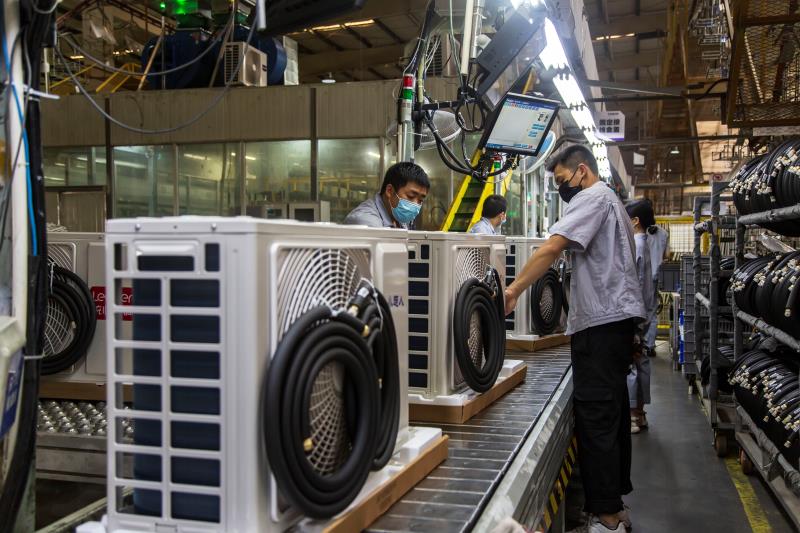

During the manufacturing process of air conditioner, assembling work is the last step. The assembly process includes assembly, adjustment, inspection and test. Finally, the design function of the air conditioner can be realized.Air conditioner Automatic assembly line is based on the transmission equipment formed by the double-speed chain transmission through the connected motor. The automatic assembly equipment controlled by PLC through the blocking and light flame switch is mainly used in the home electronics industry.

Double-speed chain automatic assembly line, in the use of various industries, such as TV assembly line, air-conditioning assembly line and other product assembly name, the main components are the body frame----speed Chain----Auxiliary Equipment-----Circulation Device----Electronic Control System.

Assembly Process:

Pre assembly →Final assembly →vacuuming →refrigerant charging→Leakage detection1→safety detection-refrigeration performance test→ leak detection2 → pasting various labels → packaging→Pre assembly

Specification

Item |

Remark |

Quantity |

Outdoor Machine |

Pre assembly line |

1 |

Final assembly line | ||

Inspection line |

1 |

|

Refrigerant leak detector |

1 |

|

Vacuum pump |

1 |

|

| Outdoor Machine test line | 1 |

|

Top system |

1 |

|

Universal ball table |

1 |

|

Packing machine |

1 |

|

Tools |

1 |

|

| Indoor hanging machine assembly Line

|

Indoor machine test line | 1 |

Top system |

1 |

|

Tools |

1 |

|

Packing machine |

1 |