info@zhengchengmech.com +86-372-2598052

info@zhengchengmech.com +86-372-2598052

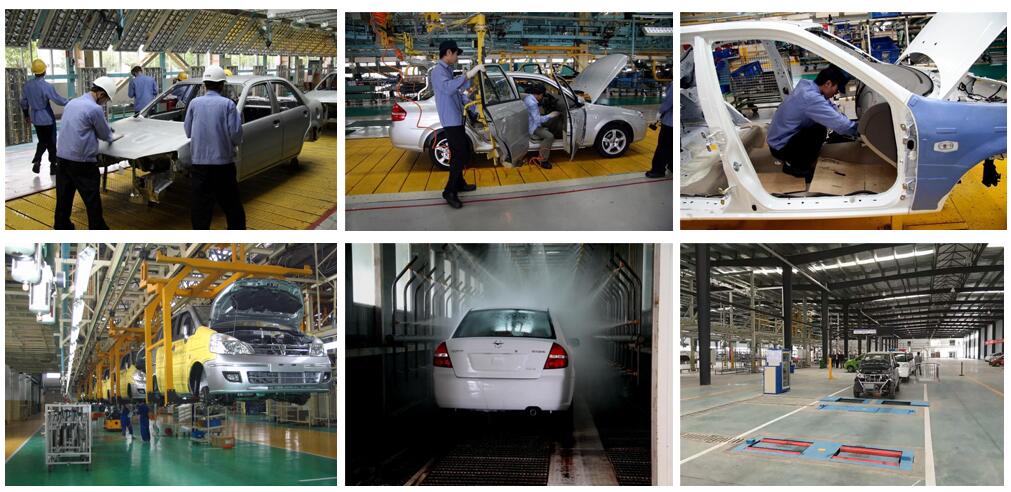

Automobile assembly line is a manufacturing process (often called a progressive assembly) in which parts (usually interchangeable parts) are added as the semi-finished assembly moves from workstation to workstation where the parts are added in sequence until the final assembly is complete vehicle. By mechanically moving the parts to the assembly work and moving the semi-finished assembly from work station to work station, a finished product can be assembled faster and with less labor than by having workers carry parts to a stationary piece for assembly.

Assembly line for car starts with a bare chassis,and components are attached successively as the growing assemblage moves along a conveyor. This automobile assembly production line are including that hanging conveyor assembly line,Trim assembly line,final assembly line,Test line and ect.

Application:

the assembly line can be use to car assembly production,bus assembly production ,electric auto assembly,SUV assembly product

Production Process:

1. Conveyor equipment: It is mainly used in automobile assembly line, assembly line of all components and conveying of large assembly on line. It can be divided into assembly line, chassis assembly line, engine assembly line, cab trim line, tire assembly line, automobile door assembly line and turnover line from each sub-assembly line to assembly line.

2.Sub-assembly and on-line equipment: the engine, front axle, rear axle, cab, wheels and other assemblies on-line sub-assembly and the transportation process to the assembly line after all parts are assembled, as well as the transportation and hoisting equipment used in the corresponding workstation.

3.Various oil filling equipment: including fuel, lubricant, cleaner, coolant, brake fluid, refrigerant and other automobile assembly line filling equipment.

4.Ex-factory Inspection equipment: including front-end test-bed, side slip test-bed, steering test-bed, headlamp detector, brake test-bed, speedometer test-bed and exhaust analyzer.

5.Special equipment: car body marking machine, thread fastening equipment, special equipment for tire assembly, automatic glue coating machine, hydraulic bridge on-line car.

FAQ:

Q:What Equipment Does ZHENGCHENG MECHANICAL Offer ?

A:We are engaged in the manufacture and sales of automatic car assembly line, motorcycle assembly line ,tricycle assembly line, bicycle assembly line,tractor assembly line,engine assembly line,TV laptop assembly line,air conditioner assembly line, automatic coating line to meet customers’different demands.

Q:Can You Send Engineer To Install And Debug Your Equipment For Us?

A:We can offer on-site installation and debugging by providing an experienced erection supervisor. Our engineers have erected assembly line all over the world and we will bring the equipment to full performance before handover.

Q:Is There Any Guarantee For Your Equipment?

A:Yes, our machines are warranted for 12 months against any manufacturing defects. Within the warranty period, we will replace the defective parts caused by machines’quality free of charge and you only pay the shipping charges. At the same time, we will provide customers with lifetime technical support. And training service on the operation of machines will also be provided for customers by us.

Q:What Is The Delivery Time For Your Equipment?

A:It is decided by the complexity of the assembly line you order. Generally, we will start manufacturing once you place the order. it takes about 35-40 days to finish the assembly line.